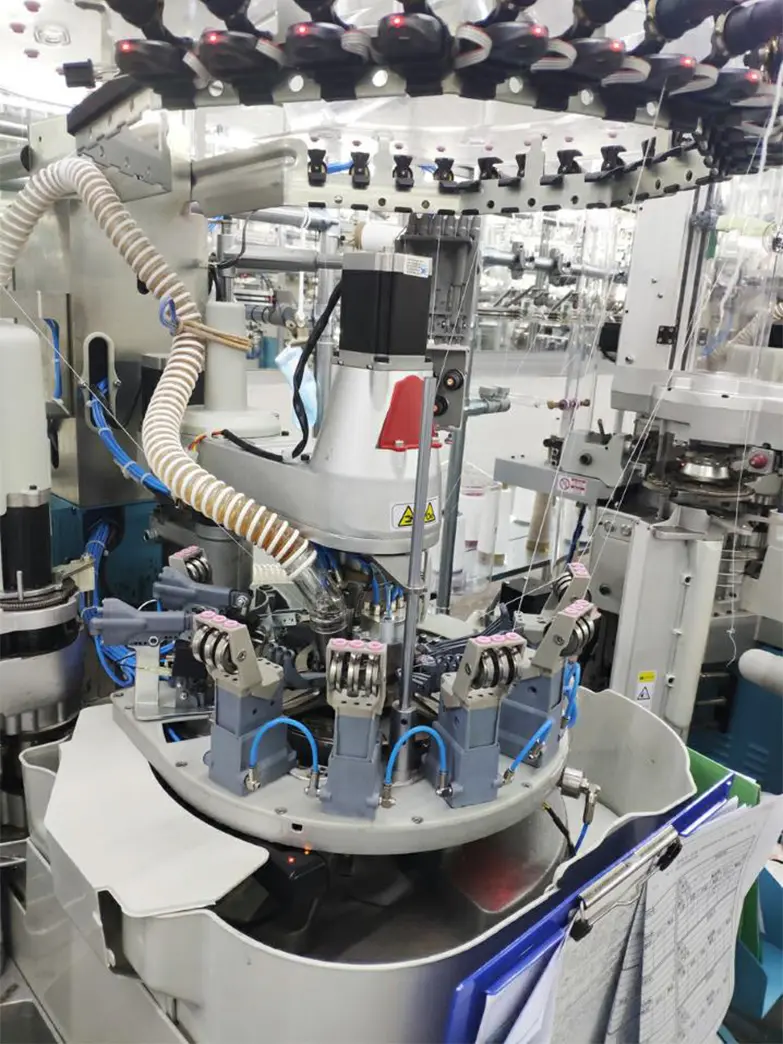

PRODUCTS

- Adult/Child Series Double Needle Casual Socks

- Thick needle series leisure socks

- Jacquard series tide socks

- Outdoor sports socks

- Socks for boys and girls

- Men's casual socks

- Girls' tights

- Women's casual socks

- Wrist bands/head bands

- Trendy Fishnet Socks

- Baby socks

- Business Gentleman Series

- Football Socks

![}]6KNMFM9G](JG4[SCM06]X.png](https://koss.iyong.com/swift/v1/iyong_public/iyong_3778183408046336/image/20200713/1594631339959008121.png)